Matching Demand to Supply: Inventory Strategies for Profit - Inbound Logistics

By Karen Kroll

Rising capital costs and escalating customer expectations make inventory mismatches—excess stock or empty shelves—a critical threat to profit and reputation. Leading brands are leveraging advanced analytics and AI solutions to tackle these challenges effectively.

With capital costs increasing, buyers are now managing cash more tightly, opting for smaller, more frequent purchases. This shift complicates demand forecasting, making it vital that suppliers enhance their capabilities to absorb variability while minimizing errors. As brands face heightened consumer expectations, they increasingly employ AI for demand sensing and to model supply scenarios, allowing for rapid decision-making and precise inventory projections.

For instance, CDW utilizes Blue Yonder's AI-driven platform to achieve accurate demand forecasting, significantly reducing excess inventory and ensuring cash flow protection. By analyzing historical sales patterns, CDW can isolate anomalies and adjust order sizes in real-time, resulting in minimal stockouts.

Similarly, GE Appliances employs agentic AI to enhance forecasting accuracy and improve operational agility through its "zero distance" strategy, which emphasizes local manufacturing. Their integrated AI tools optimize productivity and proactively address issues, leading to a 20-25% reduction in inventory levels while increasing customer satisfaction.

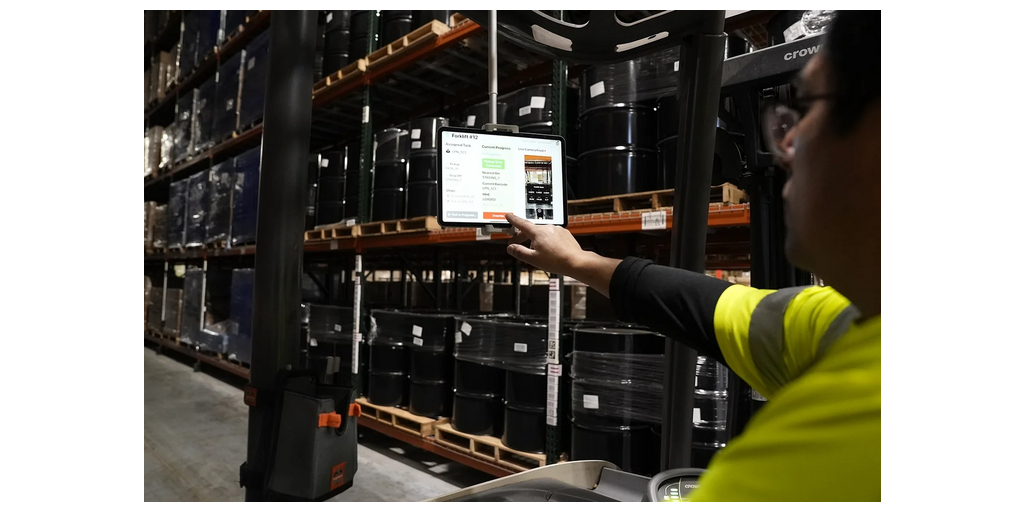

At Grainger, AI investments enhance demand forecasting and ensure smarter inventory management. In doing so, they achieve higher service levels and maximize distribution network efficiency. The ClearIce platform from Ice Mobility also integrates AI for real-time demand planning, significantly improving order accuracy and reducing stockouts.

Overall, these companies demonstrate that harnessing AI and advanced analytics not only streamlines operations but also fosters customer satisfaction and boosts profitability.