Bringing AI to the real world: GM's week at NeurIPS 2025 - General Motors

At the NeurIPS 2025 AI conference in San Diego, General Motors (GM) engaged in pivotal discussions regarding the practical applications of AI in real-world settings, particularly in autonomy and robotics. GM’s team, including Director of Autonomous Vehicle Research Ben Snyder, emphasized the importance of developing AI systems that perform safely in everyday conditions, moving beyond theoretical frameworks to operational implementations.

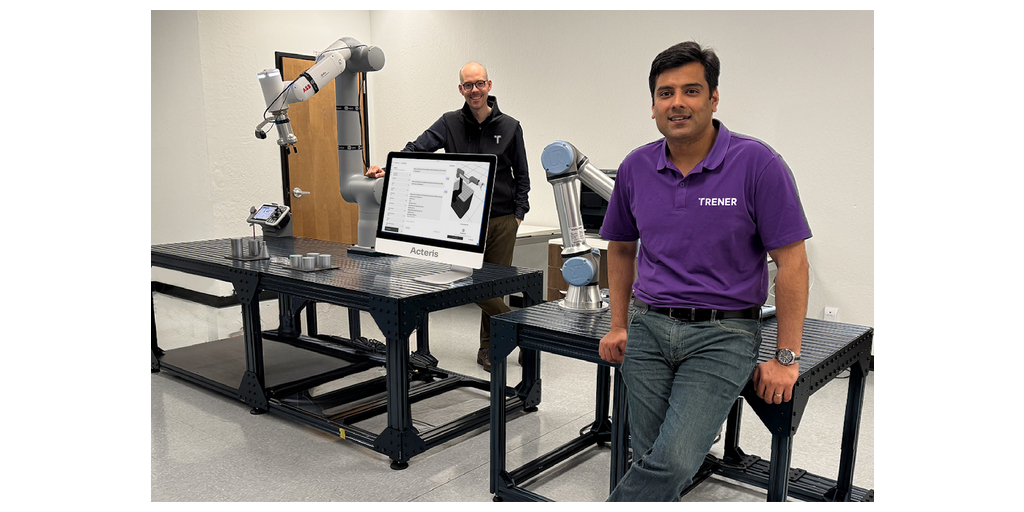

A key focus of GM’s contributions was on the application of AI in production environments. During a session titled "Practical AI for the Physical World," John Anderson, Executive Director of AI Research at GM, highlighted the integration of AI in robotics and manufacturing. He addressed GM's advancements in using AI to enhance collaborative robots for improved safety and ergonomics, ensuring these systems work efficiently in production scenarios.

The prominence of robotics at NeurIPS 2025 signaled its growing relevance within the research community, a trend that GM is keen to leverage. The interest at GM’s booth transformed from casual inquiries about autonomy and robotics to in-depth discussions about translating research into viable technologies.

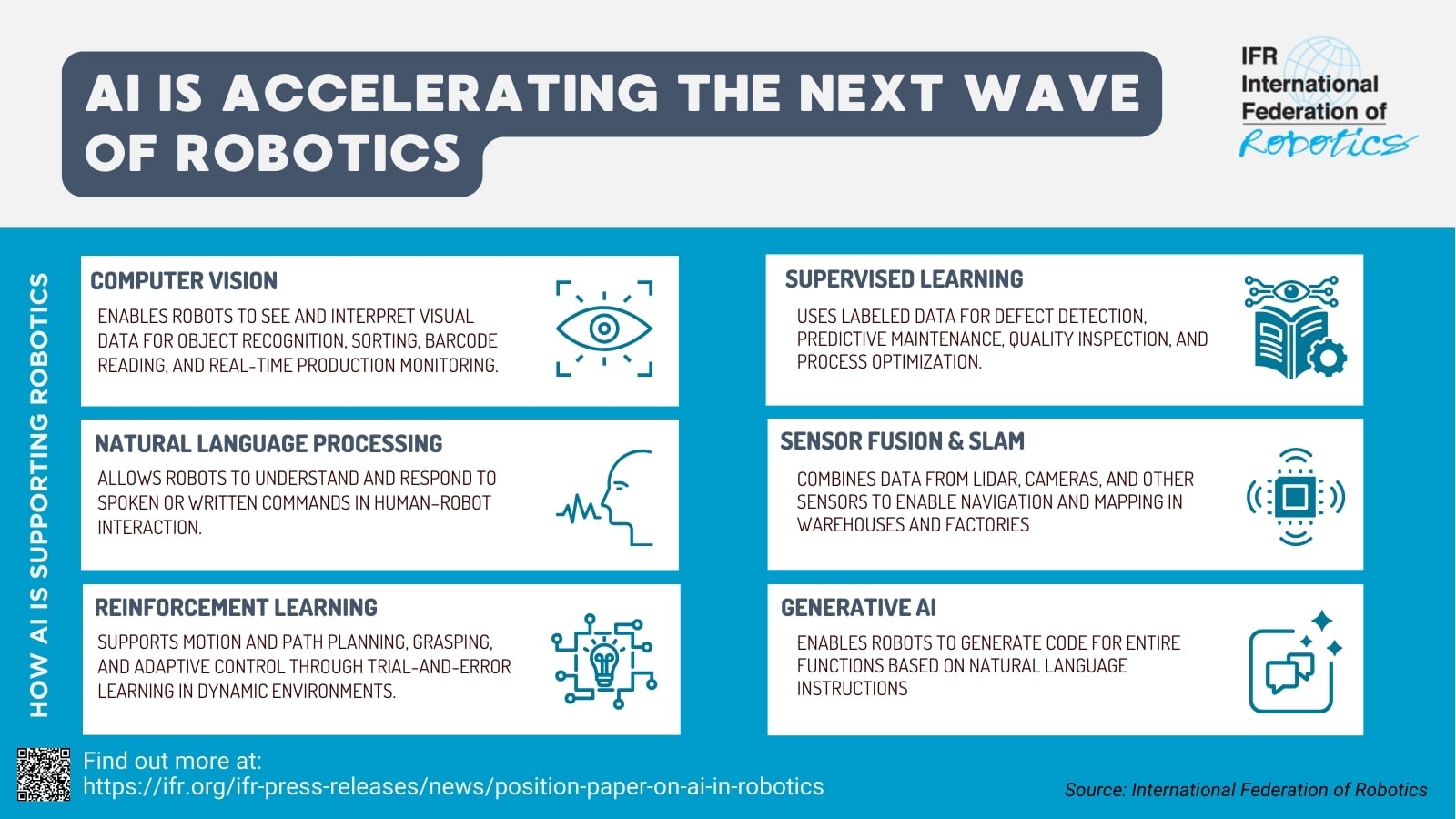

The conference culminated in GM’s Executive Mixer, led by Vice President of Autonomy Rashed Haq, which aligned industry leaders with researchers. Participants shared insights into reinforcement learning and efficient reasoning under real-world constraints, reflecting an industry shift towards practical AI applications.

GM's presence at NeurIPS 2025 not only facilitated critical exchanges on innovative AI solutions but also underscored the company's commitment to engaging with cutting-edge research, essential for advancing large-scale autonomous systems and robotics in the future.